Elevate EMI Protection:

Shielding Today, Ready for

Tomorrow

Seamless Integration of EMI Shielding in Emerging Rail Technologies

The railway industry is evolving fast. With the rise of IoT, AI, and automation, trains and infrastructure are becoming smarter, safer, and more efficient. From sensors that monitor everything from engine performance to track wear, to AI systems that adjust train schedules in real-time, technology is transforming how rail operators manage their networks.

But all this innovation comes with a catch—electromagnetic interference (EMI). As systems become more interconnected, the risk of EMI disrupting communication and causing equipment failures grows. This can lead to serious problems, especially when safety is on the line. That’s why reliable EMI shielding has become a necessity.

This article explores the growing importance of EMI shielding in today’s digital rail systems, and how nVent SCHROFF provides the products and solutions that protect the technology keeping modern trains running smoothly.

The Challenge of EMI in Rail Systems

We’ve all seen how IoT is changing industries, and rail is no exception. Sensors placed throughout the network are now constantly collecting data on everything—track conditions, train performance, even weather. This data is crucial for predictive maintenance and operational efficiency. By identifying potential issues before they cause a breakdown, IoT helps operators stay one step ahead.

At the same time, automation and AI are making their way into rail. Trains can now run autonomously, while AI systems optimize everything from scheduling to safety. But all of this relies on constant, reliable communication. When EMI interferes, it can distort data, disrupt communication, and lead to costly downtime or worse—safety risks. This is where EMI shielding becomes essential.

nVent SCHROFF is at the forefront of providing the necessary protection for digital rail systems, ensuring that everything from sensors to onboard computers continues to function smoothly, no matter the interference around them.

EMI Shielding: A Critical Part of System Protection

In a world where technology is the backbone of modern rail operations, shielding becomes more than just an option—it’s a requirement. Today’s rail systems depend on constant, uninterrupted data flow. Without it, predictive maintenance can fail, environmental sensors can provide inaccurate data, and autonomous systems can make flawed decisions.

Let’s look at a few ways EMI shielding is critical:

Predictive Maintenance:

Advanced IoT sensors installed on board of trains and in outdoor digital infrastructure boxes provide continuous condition monitoring to anticipate mechanical or structural issues. EMI shielding is crucial to ensure these data streams remain accurate and uninterrupted, enabling maintenance teams to address potential faults before they disrupt service.

Shielded enclosures, like those offered by nVent SCHROFF, protect sensitive IoT hardware from electrical interference, vibration, and environmental stress. This ensures long-term reliability of predictive maintenance systems, reducing unplanned downtime and extending asset life.

Environmental Monitoring:

Modern rail systems depend on precise environmental data such as air quality, temperature, and vibration levels to ensure safe, efficient operations. Without effective EMI shielding, sensor readings may be skewed or compromised, affecting performance and safety.

Durable enclosures and subracks from nVent SCHROFF safeguard monitoring equipment from EMI, harsh weather, and mechanical stress. This protection helps maintain consistent sensor accuracy in both indoor and outdoor environments.

AI and Automation:

AI-driven control systems depend on fast, interference-free communication between sensors, cameras, and processors to make real-time decisions. In applications like the European Train Control System (ETCS), safety relies on uninterrupted data transmission for efficient operation.

nVent SCHROFF offers EMI/RFI shielding solutions tailored for high-performance rail environments. Their rugged enclosures preserve signal integrity, supporting the safe, autonomous operation of AI and automation systems.

Supporting Rail Operators

EMI shielding is essential, but choosing the right solution for digital rail applications is critical. nVent SCHROFF understands the unique needs of the railway sector and offers a range of products designed to protect sensitive electronics in any environment.

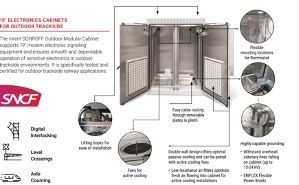

For outdoor environments, rugged trackside enclosures are built to withstand harsh weather and prevent EMI interference, ensuring that vital electronics continue to operate reliably, regardless of conditions.

For onboard systems, such as Vehicle On-Board Computers for Signaling (VOBC) and the European Train Control System (ETCS), nVent SCHROFF’s bolted rack design offers a practical, space-saving solution. It simplifies installation, reduces shipping costs, and ensures robust EMI shielding to maintain the integrity of communication systems like ETCS.

Additionally, EuropacPRO Advanced EMC Plus subracks are ideal for systems requiring high-level EMI protection. Whether for communication-based train control (CBTC) or 5G infrastructure, these subracks provide optimal shielding, ensuring seamless and safe operation. They also meet a variety of industry standards, including:

- EMC shielding (EN 61000-5-7, IEC 61587 DL 3)

- Environmental resistance (EN 50155)

- Fire safety (UL-VO, EN 45545-2)

Managing Heat in Modern

Rail Systems

Another often-overlooked challenge in today’s rail tech is thermal management. Many modern devices—especially IoT sensors and AI-powered systems—generate a fair amount of heat. If not properly managed, this heat can cause systems to overheat, reducing performance or even leading to failures.

nVent SCHROFF provides advanced cooling solutions to keep these systems at optimal operating temperatures, ensuring that devices perform reliably without the risk of overheating.

In a world where rail networks are becoming smarter and more interconnected, choosing the right EMI shielding solution partner is key to staying ahead.

For contact us for more information, please visit nvent.com/SCHROFF